We hear it all the time:

“Our operator does a walkaround, so we’re good, right?”

Not quite.

While your operator should absolutely be performing daily pre-use checks, that’s not the same as a formal inspection. In fact, having your operators inspect your cranes might be putting your business — and your workers — at risk.

Here’s why certified third-party inspections are essential:

🎯 1. Operators Are Not Trained Inspectors

Your team knows how to run the crane — but they likely haven’t been trained to spot structural defects, evaluate load systems, or check for CSA B167 compliance. Professional inspectors bring specialized knowledge and tools to the job.

👀 2. Familiarity Can Blind You

When someone works with the same equipment every day, they often stop seeing the “small stuff.” Hairline cracks, frayed wire ropes, or slipping brakes may be dismissed as normal — until they fail.

⚠️ 3. Liability Falls on YOU

If an incident occurs and your last “inspection” was a quick visual check by the operator, you’re exposed to:

-

WCB issues

-

OH&S violations

-

Insurance claim disputes

-

Serious injury investigations

📅 4. Inspection Records Matter

Third-party inspections include:

-

Legally recognized reports

-

Timestamped deficiency tracking

-

Repair and compliance documentation

-

Maintenance logs that stand up in audits

🛠️ 5. Teamwork Works Best

The best safety systems involve everyone:

-

Operators perform daily pre-use checks

-

Certified techs conduct formal monthly/annual inspections

-

Management tracks and responds to reports

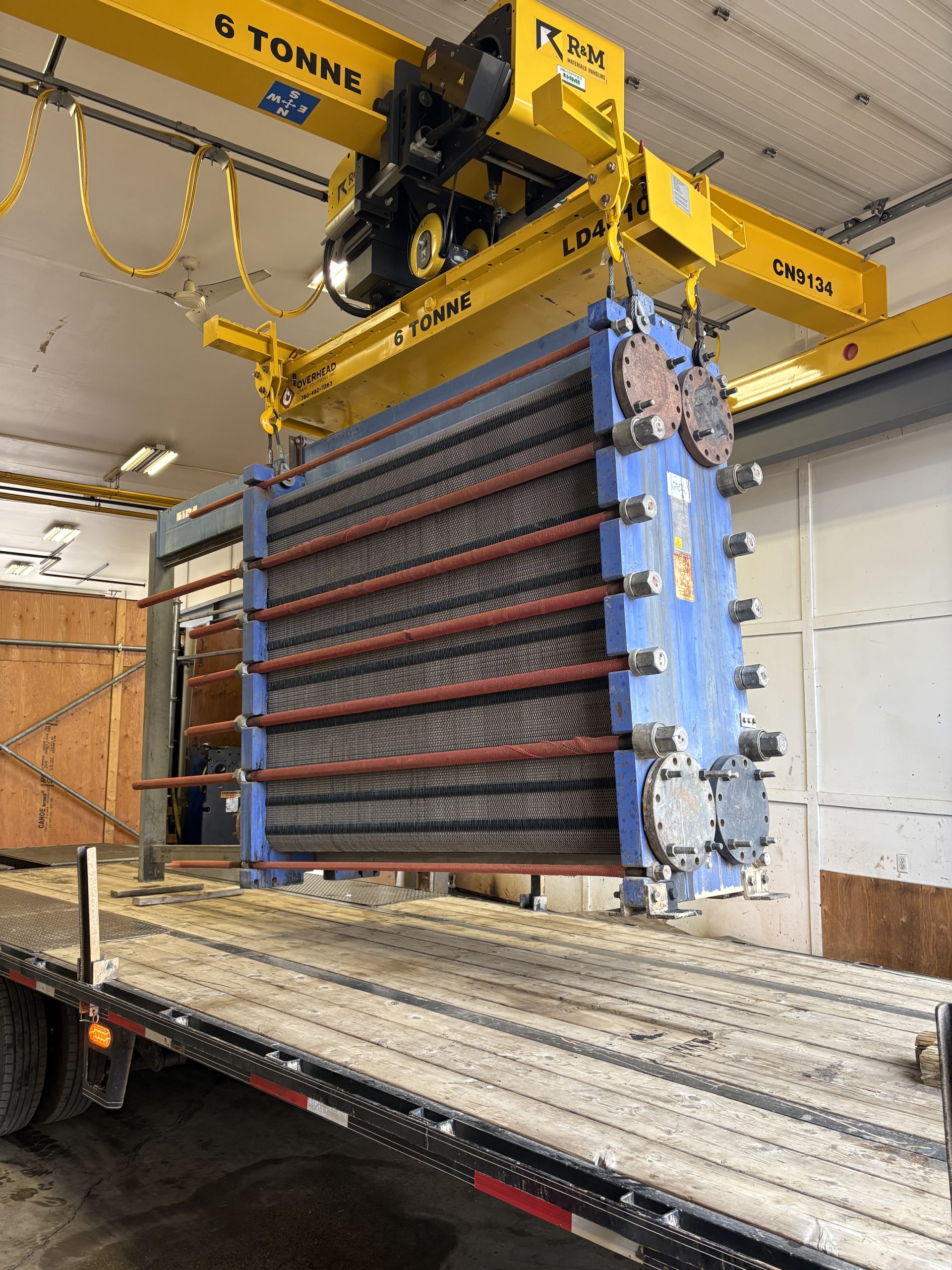

🔍 Call in the Pros

At Overhead Crane Solutions, our certified inspectors are trained to meet CSA and OH&S requirements. We don’t just check boxes — we help you stay safe, compliant, and efficient.

📞 780-482-7263

📍 Serving Alberta from our Nisku HQ

🌐 www.overheadcranesolutions.com