When it comes to material handling and overhead lifting, no two workplaces operate the same way. From ceiling height and runway length to load weight, environment, and workflow demands, each facility has its own unique challenges. That’s why choosing a one-size-fits-all crane doesn’t always deliver the performance, safety, or efficiency that your operation needs. In many cases, a custom-engineered crane is not just an upgrade — it’s the best long-term investment.

Standard Cranes vs. Custom-Engineered Cranes

Standard cranes are designed with preset capacities, spans, speeds, and features. They perform well in straightforward environments and are often ideal for general use or new construction where the building can be designed to match the crane.

Custom cranes, on the other hand, are engineered around your actual facility — not the other way around. They’re built to solve specific lifting challenges, fit into existing infrastructure, and support specialized production, repair, or handling processes.

What Makes Custom Cranes So Valuable?

🔹 Optimized for Your Space

Some facilities have tight clearances, uneven layouts, limited support structure, outdoor lifting needs, or heavy production traffic. A custom design ensures the crane fits perfectly into the space and operates safely without compromising workflow.

🔹 Built for Your Load & Usage

Whether you’re lifting delicate components or heavy industrial equipment, custom cranes can be engineered for:

-

Exact capacity requirements

-

Specific duty cycle demands

-

Hook coverage and precise positioning

-

Specialized attachments or rigging

This means no over-buying — and no under-building.

🔹 Improved Safety & Compliance

A crane that doesn’t suit the space or job can lead to risk — from near misses to structural failure. Custom systems reduce hazards by aligning engineering with real-world conditions, safety codes, and operational expectations.

🔹 Enhanced Productivity & Workflow

When a crane is designed around your process, it becomes a productivity tool, not just lifting equipment. Custom cranes help reduce bottlenecks, eliminate unnecessary manual handling, and speed up repetitive tasks, all while supporting ergonomic and efficiency goals.

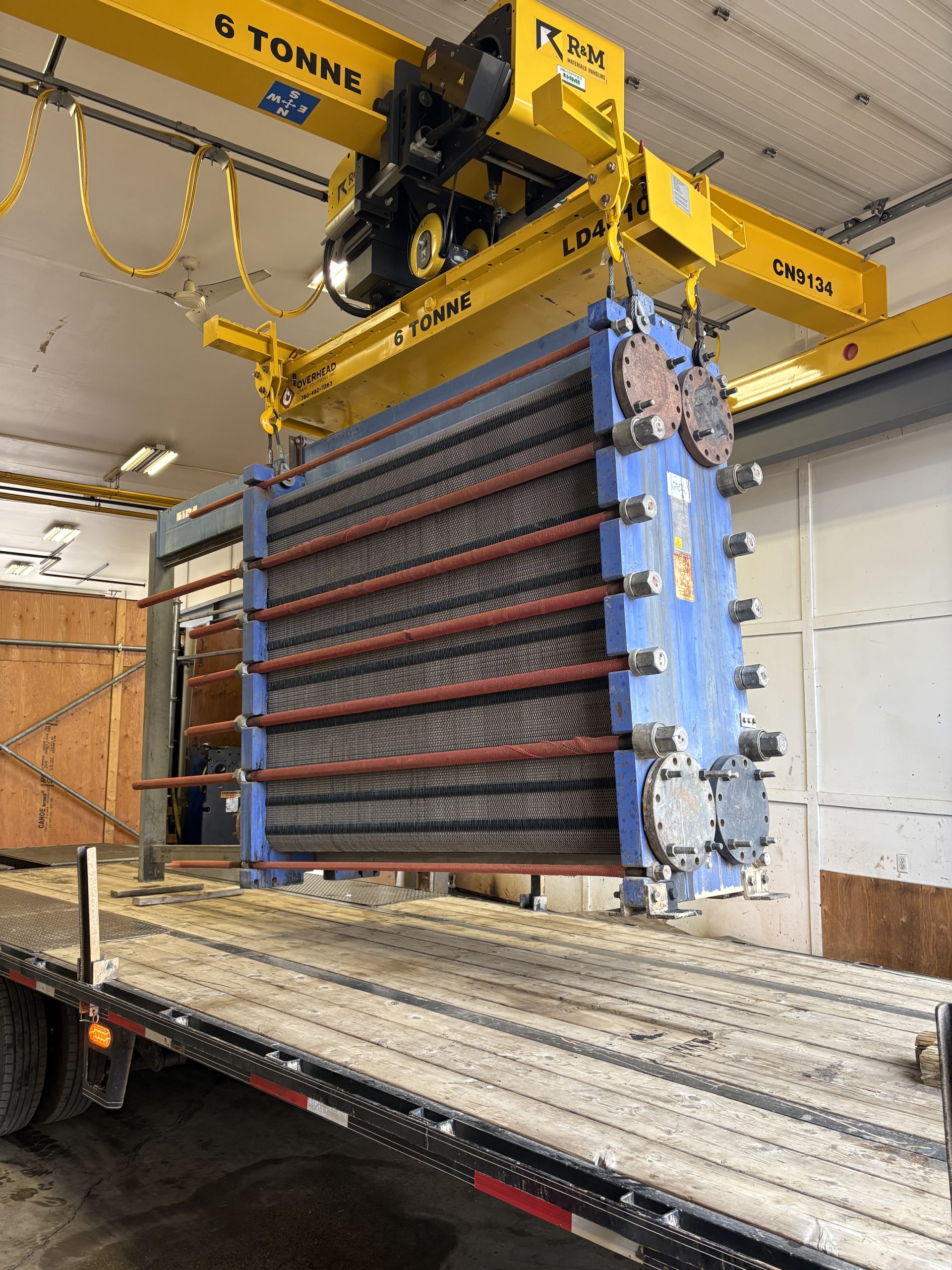

Real-World Example: Custom Installation in Action

The image above shows one of our recent custom builds being installed on site. This particular project required tailored planning, specialized lift equipment, and precise execution to ensure correct fit, safe handling, and long-term performance. These are the kinds of installs where custom engineering truly shines — combining innovation, safety, and craftsmanship.

Thinking About a Crane Solution?

Whether you’re modifying an existing building, expanding production, or dealing with unique lifting challenges, our team is here to help engineer a system that fits your needs — not the other way around.

Let’s talk about your space, your load, and your goals.

📞 780-482-7263

📧 info@overheadcranesolutions.com

🌐 www.overheadcranesolutions.com