Overhead cranes are vital for efficiently lifting and moving heavy loads within a workspace or facility. These systems enhance productivity, improve workflows, and ensure the safety of both workers and products. Overhead cranes come in various sizes and classifications tailored to meet the specific needs of industries such as agriculture, aviation, automotive, construction, and manufacturing. Here’s a breakdown of different types of overhead cranes, their specific uses, and key features to help you decide which crane system is best for your business.

1. Workstation Cranes

- Use Case: Ideal for smaller work areas and lighter loads.

- Capacity: 150 lbs. – 2 tons.

- Features: Suitable for positioning loads and repetitive light-duty lifting. These cranes have a modular design and components, meaning they don’t require an existing structural support system.

2. Jib Cranes

- Use Case: Perfect for repetitive lifting in smaller work areas.

- Capacity: 250 lbs. – 15 tons.

- Features: Offers 180° to 360° rotation. Typically mounted to the floor (stand-alone) or a structural wall, eliminating the need for a track or runway system.

3. Monorail Cranes

- Use Case: Suited for assembly and production lines where movement is linear.

- Capacity: Varies based on design.

- Features: Incorporated into an existing structural I-beam, making them cost-effective. They provide back-and-forth movement on a straight or curved track, with no side-to-side travel.

4. Gantry Cranes

- Use Case: Ideal for outdoor locations needing quick setup and tear-down in multiple work areas.

- Capacity: Varies based on design.

- Features: Legs travel along rails supported by the floor or ground, rather than a suspended runway. Popular in steel mills, special construction projects, shipyards, and railyards.

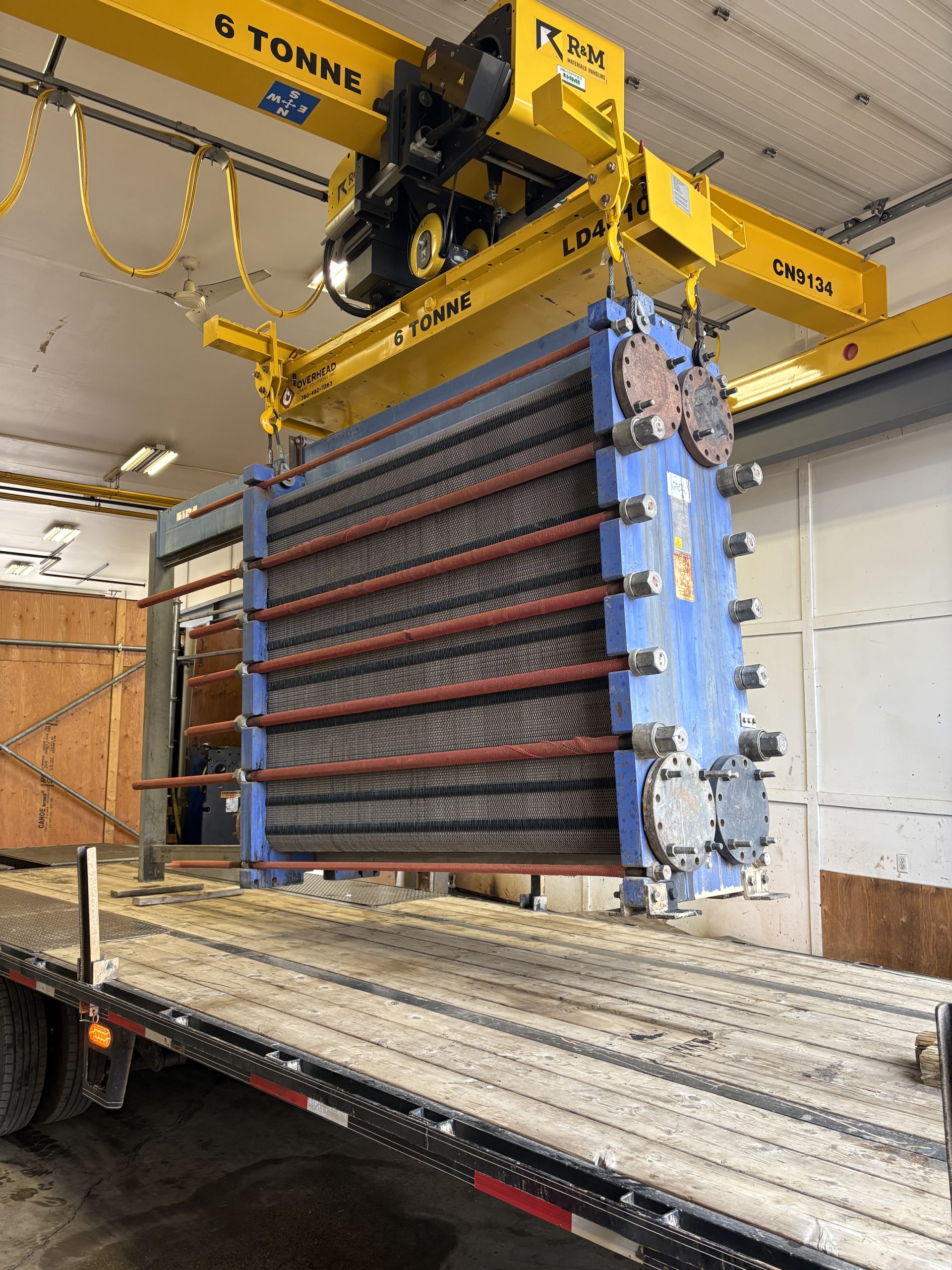

5. Overhead Bridge Cranes

- Types:

- Single Beam or Girder Cranes:

- Use Case: Best for lifts under 15 tons and spans of up to 65 feet.

- Features: Requires fewer parts, leading to faster installation, lower maintenance costs, and a simpler hoist and trolley design.

- Double Beam or Girder Cranes:

- Use Case: Suitable for heavy-duty applications exceeding 25-ton lifts and spans over 65 feet.

- Features: Ideal for customizations like cabs, magnet reels, and walkways.

- Single Beam or Girder Cranes:

- Configurations:

- Top Running: The bridge crane runs on rails atop the runway beams.

- Under Running (Underhung): The crane wheels are supported by the bottom flange of the runway beam.

Choosing the Best Overhead Crane for Your Business

With multiple crane options available, selecting the best one for your business involves evaluating your specific needs and physical location requirements. Consider these key questions:

- Facility Size: How large is your facility? Bridge cranes can span up to 220+ feet.

- Building Construction: Can your building structure support the crane and its load, or will it require reinforcement?

- Indoor or Outdoor Location: Consider weather exposure and elemental protection.

- Temperature: Is the facility subject to extreme temperatures? This may influence crane design and materials.

- Load Capacity: What weight will the crane need to lift? Capacities range from 125 kg to over 200 tons.

- Operational Demand: How many loads per hour and hours per day will the crane operate? This determines the hoist and trolley requirements.

- Range of Movement: Does the crane need side-to-side travel, or is linear movement sufficient?

- Precision vs. Speed: Will the crane require rapid lifting or precise control?

- Exposure to Harmful Factors: Will the crane be exposed to chemicals, gases, moisture, or corrosive materials?

By answering these questions, you can narrow down the best overhead crane system for your specific operational needs.