What is a Gantry Crane?

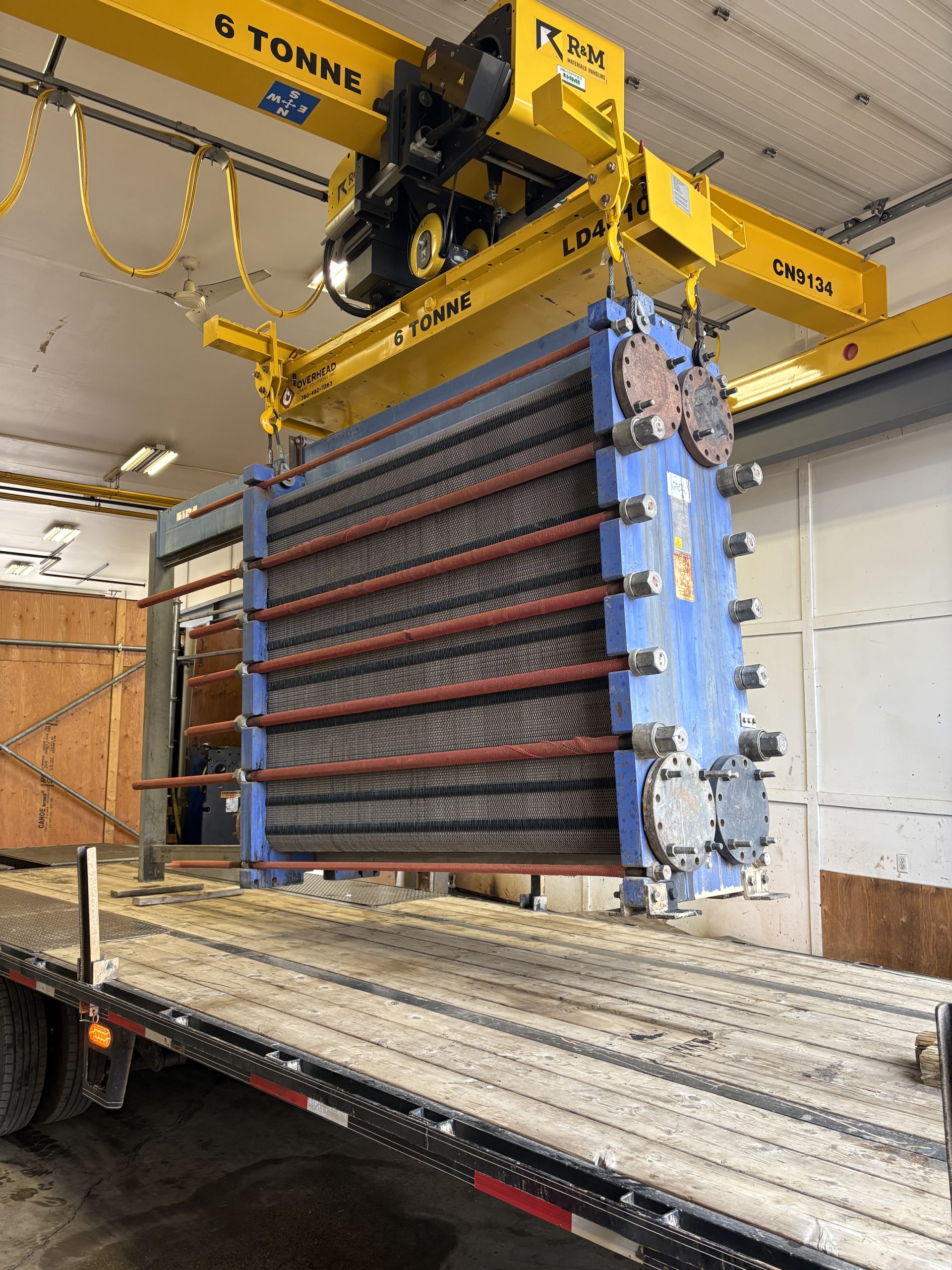

A gantry crane is a type of overhead crane supported by freestanding legs that run on wheels or tracks. Unlike fixed overhead cranes, gantry cranes don’t require a building or permanent structure to operate, making them highly versatile. They’re available in various configurations, ranging from portable models for light loads to massive structures capable of lifting hundreds of tons.

Uses of Gantry Cranes

Gantry cranes are widely used across multiple industries due to their adaptability and strength. Here are some common applications:

- Manufacturing

- Ideal for assembling heavy machinery, moving raw materials, and transporting finished products within production facilities.

- Construction

- Used to lift and place heavy building materials like steel beams, concrete blocks, and prefabricated sections.

- Shipbuilding and Ports

- Essential for handling large cargo containers, engines, and other components during ship assembly or at loading docks.

- Warehousing and Logistics

- Perfect for loading and unloading freight in distribution centers and moving goods within storage facilities.

- Aerospace and Automotive Industries

- Used to lift and position large components like airplane wings, fuselages, or vehicle bodies during assembly and repair.

- Small Workshops and DIY Projects

- Portable gantry cranes are excellent for hobbyists or small-scale operations requiring precise lifting.

The Need for Gantry Cranes

Modern industries rely on gantry cranes to meet demands for efficiency, precision, and safety. Here’s why they’re essential:

- Handling Heavy Loads

- Gantry cranes are specifically designed to lift and move materials that would otherwise be impossible with manual labor or smaller equipment.

- Space Optimization

- Unlike traditional overhead cranes, gantry cranes don’t require additional building structures. Their freestanding design allows for easy setup in outdoor or space-limited environments.

- Flexibility

- With adjustable heights and spans, gantry cranes can adapt to different load sizes and workspaces, offering unmatched versatility.

- Cost-Effectiveness

- For operations that don’t require permanent crane installations, gantry cranes provide a budget-friendly alternative without compromising on functionality.

- Safety and Precision

- Advanced controls and safety features ensure that heavy loads are moved with accuracy, reducing the risk of accidents.

Benefits of Using Gantry Cranes

Investing in a gantry crane brings a host of advantages to your operations:

1. Portability

- Many gantry cranes, especially smaller models, are portable and can be easily moved to different locations. This makes them ideal for operations that require mobility.

2. Customization

- Gantry cranes come in a variety of configurations:

- Single Girder: Lightweight and cost-effective for smaller loads.

- Double Girder: Higher load capacity for heavy-duty operations.

- Adjustable Models: Adaptable to different heights and spans.

3. Durability and Longevity

- Designed to withstand heavy loads and harsh environments, gantry cranes offer excellent durability, reducing the need for frequent replacements.

4. Ease of Installation and Maintenance

- Unlike fixed cranes, gantry cranes are easier to set up and maintain, saving time and resources.

5. Increased Productivity

- By automating heavy lifting tasks, gantry cranes free up workers to focus on other aspects of the job, significantly boosting overall efficiency.

6. Environment-Friendly Options

- Modern gantry cranes come with energy-efficient systems, reducing power consumption and the environmental footprint of operations.

Gantry Crane Selection Tips

When choosing a gantry crane for your operation, consider the following:

- Load Capacity: Ensure the crane can handle your maximum load requirements.

- Span and Height: Select dimensions that suit your workspace.

- Mobility Needs: Opt for portable models if you require flexibility.

- Material: Aluminum for lightweight portability or steel for heavy-duty durability.

- Safety Features: Look for overload protection, emergency stop systems, and advanced controls.

Conclusion

Gantry cranes are more than just lifting machines—they’re essential tools that drive productivity, enhance safety, and reduce operational costs across industries. Whether you’re in manufacturing, construction, or logistics, a well-chosen gantry crane can revolutionize your workflow.

If you’re considering adding a gantry crane to your operations, let our team of experts guide you through the process. From selection to installation and maintenance, we’re here to ensure your lifting needs are met with precision and reliability.

Ready to lift smarter? Contact us today to find the perfect gantry crane solution for your business.