Investing in a new overhead crane is a significant decision for any facility. Whether you’re expanding operations, replacing aging equipment, or upgrading to meet safety and efficiency demands, understanding the installation process can help ensure a successful outcome. At Overhead Crane Solutions Inc., we pride ourselves on delivering safe, efficient, and turnkey crane installations. Here’s a step-by-step look at what the process involves:

1. Initial Consultation and Site Assessment

Every crane installation begins with a conversation. Our experts discuss with your team the following:

-

Your lifting requirements (capacity, span, height of lift)

-

Type of crane system (bridge crane, gantry crane, jib crane, etc.)

-

Usage frequency and operating environment

-

Building structure and obstructions

We conduct a site assessment to inspect the physical space, existing supports, and confirm compliance with applicable codes and CSA standards.

2. Engineering and Custom Design

Next, our engineering team develops a custom crane system tailored to your needs. This includes:

-

Structural analysis of the building or runway system

-

Selection of hoists, trolleys, and controls

-

Load calculations and safety factors

-

Drawing packages for approval

Designs are reviewed with your team to ensure functionality and future serviceability.

3. Fabrication and Component Sourcing

Once approved, fabrication begins. This involves:

-

Manufacturing structural components (beams, girders, end trucks)

-

Sourcing hoists, control panels, radio remotes, and safety features

-

Painting and corrosion protection, especially for outdoor or corrosive environments

We work with trusted vendors to ensure that all components meet industry safety and quality standards.

4. Site Preparation

Before installation day, the site must be ready. This may include:

-

Clearing access routes and crane bay

-

Ensuring floor loads are adequate for equipment and lifting

-

Installing or reinforcing runway beams and support columns

-

Scheduling shutdowns or limited access in active production areas

Our team coordinates with your facility to minimize disruption.

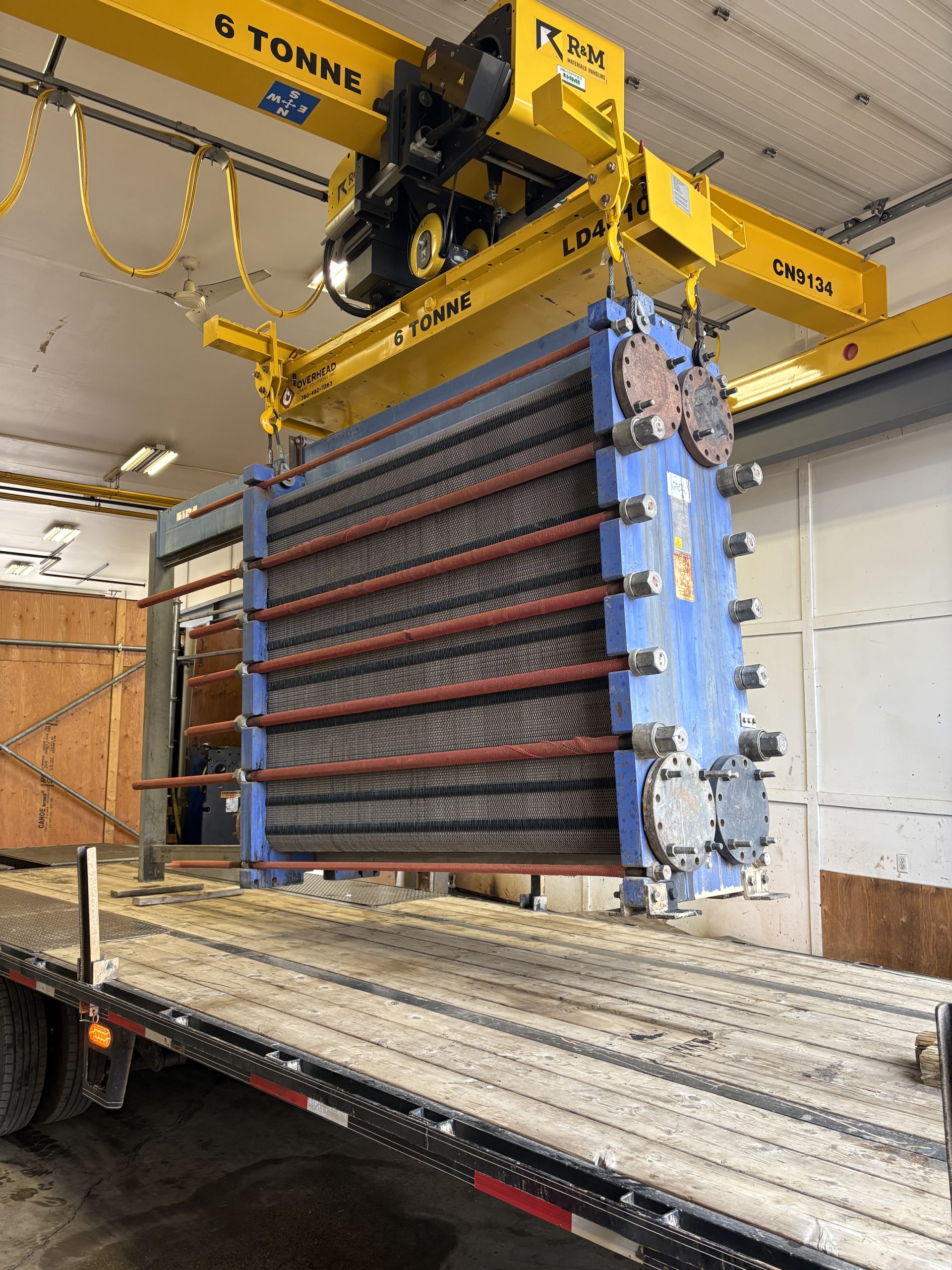

5. Crane Installation

Installation typically includes:

-

Delivery and rigging of crane components

-

Assembling and securing girders, trolleys, hoists, and electrification

-

Installing end stops, festoons, and safety limit switches

-

Connecting power supply and control wiring

All work is performed by certified technicians, and installation follows CSA B167 standards and other applicable safety regulations.

6. Load Testing and Commissioning

No crane is put into service without thorough testing. This phase includes:

-

Static and dynamic load testing (typically up to 125% of rated capacity)

-

Functional testing of all movement, brakes, and limit switches

-

Calibration of variable frequency drives (VFDs) and control systems

-

Final inspection and documentation

We ensure everything operates smoothly before handing it over.

7. Operator Training and Turnover

We can provide full training for your operators, covering:

-

Crane and hoist operation

-

Emergency procedures and safety features

-

Daily inspection and maintenance protocols

-

Understanding load charts and safe lifting practices

You’ll receive a complete turnover package including inspection certificates, drawings, manuals, and warranty details.

8. Ongoing Support and Preventive Maintenance

After installation, Overhead Crane Solutions Inc. remains your partner for:

-

Preventive maintenance programs

-

24/7 emergency repair services

-

Annual CSA inspections

-

Upgrades and retrofits

A properly installed and maintained crane will serve you reliably for years to come.

Final Thoughts

Installing a new overhead crane isn’t just about the equipment—it’s about improving productivity, safety, and workflow. From planning to commissioning, our team ensures a seamless experience. If you’re considering a new crane or expanding your lifting capabilities, reach out to Overhead Crane Solutions Inc. today.

📞 Call 780-482-7263

🌐 www.overheadcranesolutions.com

📩 info@overheadcranesolutions.com