As the weather warms up and businesses ramp up operations, spring is the perfect time to ensure your overhead cranes, welding equipment, and material handling systems are in peak condition. Routine inspections, calibrations, and upgrades can help you avoid costly downtime and keep your equipment running safely and efficiently.

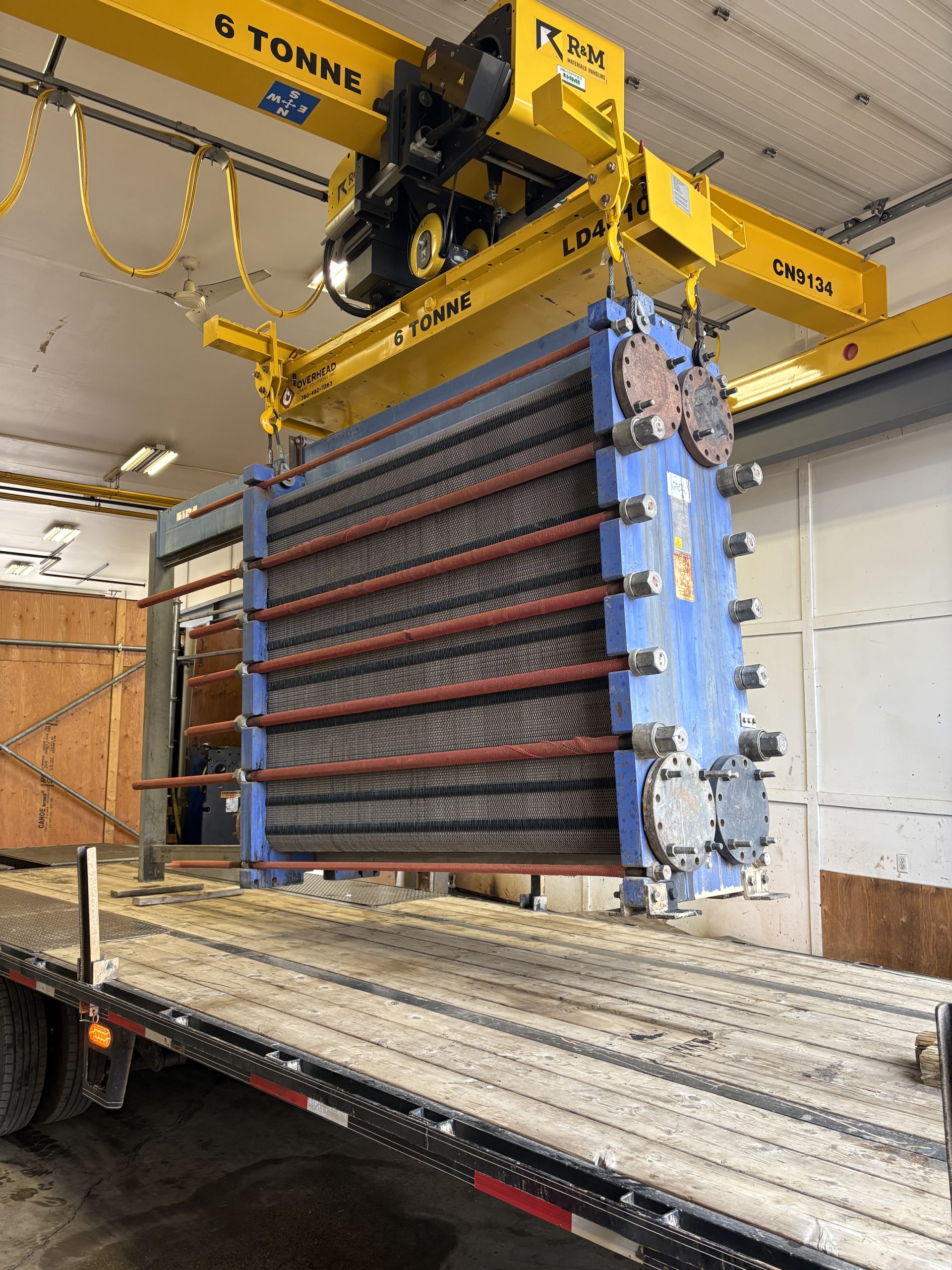

1. Spring Overhead Crane Maintenance: A Fresh Start

Overhead cranes are essential for heavy lifting, and after months of winter wear, it’s crucial to perform a comprehensive spring maintenance check. Here’s what should be on your checklist:

✔ Inspect Wire Ropes & Chains – Check for fraying, kinks, or corrosion. Worn-out components can lead to dangerous failures.

✔ Lubricate Moving Parts – Cold weather can cause grease and lubricants to harden. Spring is the perfect time for a reapplication.

✔ Check Electrical Components – Moisture buildup over winter can affect electrical connections. Inspect control panels, wiring, and limit switches.

✔ Test Brakes & Load Limiters – Ensure all safety mechanisms are functioning properly before increasing workload for the season.

📢 Pro Tip: Scheduling regular overhead crane inspections and maintenance ensures compliance with safety regulations and extends the life of your equipment.

2. Welding Calibration: Precision for the Busy Season

If your shop relies on welding for structural fabrication, equipment repair, or custom builds, spring is an ideal time to calibrate welding machines. Proper calibration ensures:

✅ Consistent Weld Quality – Avoid defects and rework due to improper heat settings.

✅ Increased Efficiency – Well-calibrated machines minimize material waste and downtime.

✅ Compliance with Industry Standards – Ensure your welds meet safety and quality requirements.

Whether you use MIG, TIG, or stick welding, ensuring your machines are properly set up will help you stay productive and profitable in the months ahead.

3. Thinking About a New Crane? Now’s the Time!

If your operation is growing or your existing cranes are showing signs of wear, spring is a great time to invest in a new overhead crane. Benefits of upgrading include:

🏗️ Increased Lifting Capacity – Ensure your crane can handle heavier loads safely.

⚙️ Modern Safety Features – New cranes come with advanced automation and enhanced safety controls.

💰 Long-Term Cost Savings – A new, energy-efficient crane reduces operational costs and minimizes maintenance expenses.

Considering an upgrade? Our team can help you design, install, and maintain a crane system tailored to your needs.

Prepare for a Productive Season

Spring is all about renewal, growth, and efficiency. Whether it’s maintaining your cranes, calibrating your welding equipment, or investing in new solutions, taking action now will keep your business running smoothly throughout the year.

📞 Need help with inspections, maintenance, or new equipment? Contact us today!