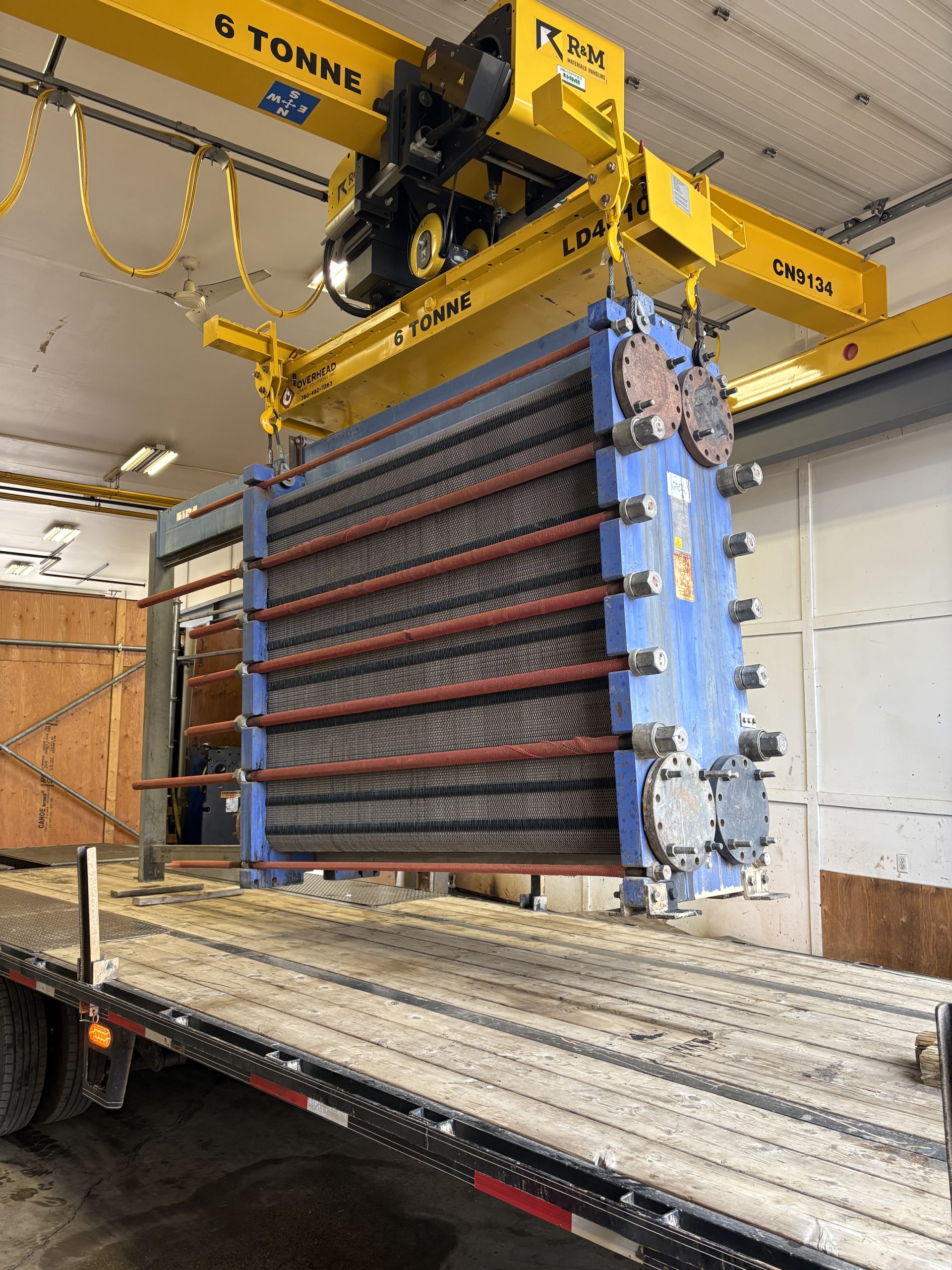

Overhead cranes are essential for lifting and moving heavy loads across various industries. Due to their power and complexity, they pose significant safety risks if not operated and maintained properly. Here’s a comprehensive guide to ensure safety when operating and working around overhead cranes.

Functions and Operations of Overhead Cranes

Overhead cranes are versatile machines used to lift, move, and position heavy loads within industrial environments. These cranes come in various forms, including:

- Bridge Cranes: Installed on parallel beams, with a traveling bridge that moves the load.

- Gantry Cranes: Free-standing, with a beam supported by legs and swivel casters.

Key Components:

- Electric Wire Ropes or Chain Hoists: Used to lift and lower loads.

- Hoisting Connections: Electromagnets, hooks, and slings attach to the load.

Operator Responsibilities:

- Oversee load hookups.

- Control crane movements.

- Ensure adherence to safety requirements.

General Safety Requirement Checklist

- Be Aware of Your Surroundings

- Operator Awareness: Ensure the load path is clear of people and obstacles.

- Area Safety: Keep the work area free from unnecessary personnel and obstructions.

- Communication: Workers around the crane should be informed about crane operations and safety protocols.

- Lift Loads Within the Crane’s Limits

- Weight Limits: Adhere to the crane’s maximum weight capacity to prevent damage and ensure safety.

- Load Checks: Verify load weight before lifting and choose a crane that meets your lifting needs.

- Perform Preventive Maintenance

- Regular Checks: Conduct routine maintenance to address small issues before they escalate.

- Maintenance Tasks: Include tasks such as oil changes, filter replacements, and system checks.

- Operate Cranes With Proper Training

- Certification: Ensure operators have the necessary licenses or certifications as per local regulations.

- Training: Provide comprehensive training on crane operation and safety protocols.

- Inspect the Crane Daily

- Pre-Use Inspection: Conduct a visual check of the crane at the beginning of each shift.

- Inspection Items: Examine air and hydraulic systems, hoisting connections, electrical systems, and safety devices.

Gantry Crane Safety

Gantry cranes have specific safety considerations due to their design and use:

- Installation:

- Ensure proper leveling and alignment of the crane.

- Verify that the legs are equally aligned and the crane sits on stable ground.

- Movement and Operation:

- Leg Stability: Use brakes or stop blocks to prevent unintended movement while attaching or detaching loads.

- Swinging Loads: Be cautious of load swinging when moving the crane; ensure the load is securely attached and balanced.

Additional Safety Considerations:

- Avoiding Hazards:

- Do not walk under suspended loads.

- Keep clear of the crane’s moving parts and avoid placing yourself in the crane’s load path.

- Emergency Procedures:

- Familiarize yourself with emergency stop procedures and ensure all operators and workers know how to react in case of a malfunction or accident.

- Regular Training and Drills:

- Conduct safety drills and refresher training sessions regularly to keep all personnel aware of the latest safety practices and procedures.

By following these guidelines and maintaining a strong focus on safety, you can help ensure the safe and efficient operation of overhead cranes in your workplace.