What Are Jib Cranes?

Jib cranes are versatile lifting devices featuring a horizontal arm, or “jib,” that extends out from a central mast. This design allows jib cranes to reach and lift loads with arc-like or lateral movements, making them highly adaptable for various industrial tasks. They are often employed in smaller work areas or for repetitive lifting tasks due to their flexibility and efficiency.

Applications of Jib Cranes

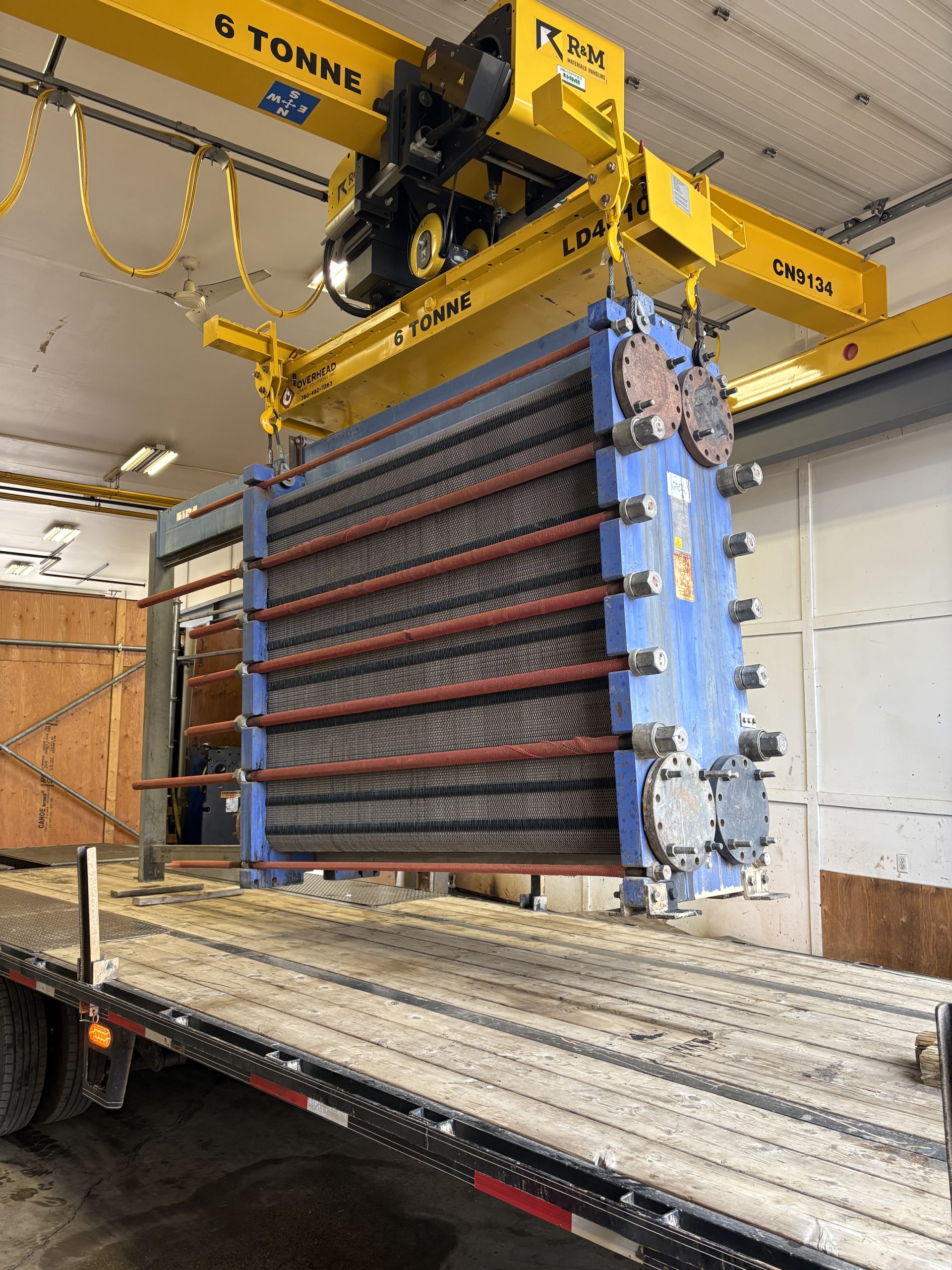

- Shipping: Jib cranes are used for loading and unloading materials from ships and trucks. Heavy-duty models can handle large and heavy items efficiently.

- Construction: In construction sites, jib cranes are valuable for moving loads to difficult-to-reach areas.

- Warehousing: Warehouses use jib cranes to handle and move materials within inventory systems. They offer precise control for placing loads on production lines or specific storage locations.

Key Components of Jib Cranes

- Boom: The horizontal beam of the crane that extends from the mast and moves in a rotational manner. It typically spans between 180 and 360 degrees. The boom includes the hoist, which lifts the load.

- Mast: The vertical support structure that anchors the boom. It provides stability and is usually anchored to the floor or wall.

- Hoist: The mechanism attached to the boom responsible for lifting loads. Hoists can be manual, pneumatic, or electric and use wire ropes, chains, or levers depending on the application.

- Trolley: Supports and facilitates the movement of the boom. The trolley remains stationary while the hoist operates.

- Festoon System: Manages the power cables and ensures they are safely and effectively delivered to the trolley and boom. Useful for longer booms.

- Power Source: Jib cranes can be powered by electrical, pneumatic, or hydraulic sources. Operators often use push-button controls for operation.

Types of Jib Cranes

- Freestanding Jib Cranes:

- Description: Supported by a base plate or foundation, these cranes are suitable for both indoor and outdoor use.

- Features: Wide capacity reach and high flexibility in installation.

- Wall Traveling Jib Cranes:

- Description: Mounted on rails attached to the walls of a building, allowing the crane to move along the wall.

- Features: Ideal for moving loads efficiently within a facility. Can be integrated with overhead cranes for enhanced lifting solutions.

- Wall-Mounted Jib Cranes:

- Description: Attached directly to walls, these cranes do not require floor space.

- Features: Space-saving design with options for cantilever or tie-rod-supported structures. Can be folded against the wall when not in use to avoid obstructions.

- Mast Type Jib Cranes:

- Description: Supported by both the floor and ceiling beams, taking up minimal floor space.

- Features: Ideal for facilities where floor space is limited, and no alterations to foundations or ceilings are needed.

Choosing the Right Jib Crane

Selecting the appropriate jib crane depends on several factors:

- Load Capacity: Ensure the crane can handle the maximum weight of the loads you intend to lift.

- Space Availability: Consider the layout of your facility and whether a freestanding or wall-mounted model is more suitable.

- Application Requirements: Match the crane type to the specific needs of your operations, such as the need for mobility or fixed positioning.

- Environment: Factor in whether the crane will be used indoors or outdoors and the impact of environmental conditions on the crane’s operation.

Jib cranes provide a practical and adaptable solution for various lifting needs, enhancing productivity and safety in numerous industrial settings.