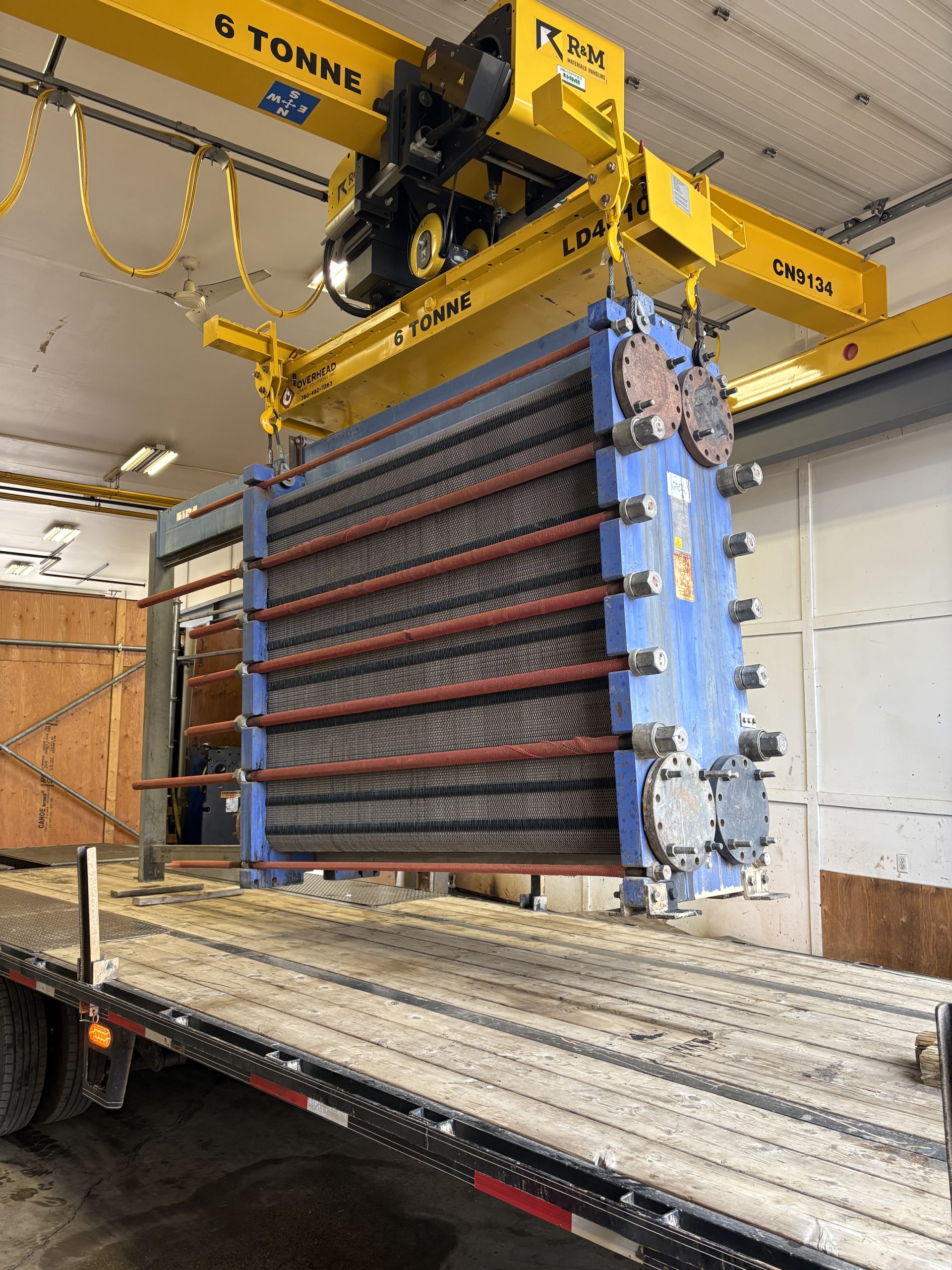

Overhead cranes are an excellent choice for many businesses looking to improve efficiency, safety, and space utilization in their facilities. Here’s a detailed look at why and when your business might benefit from installing an overhead crane:

Key Benefits of Overhead Cranes

- Increased Worker Safety:

- Reduced Physical Strain: Overhead cranes can help mitigate repetitive strain injuries (RSIs) by minimizing the need for workers to manually handle heavy materials.

- Elimination of Clutter: By moving the lifting and transporting tasks overhead, cranes reduce clutter and the risk of slips and falls, creating a safer work environment.

- Enhanced Productivity and Efficiency:

- Streamlined Movement: Cranes allow for more efficient movement of materials compared to forklifts and conveyors, particularly in tight spaces or complex layouts.

- Reduced Floor Space Use: Cranes operate overhead, freeing up valuable floor space for other activities and improving overall workflow.

- Space Optimization:

- Compact Footprint: Overhead cranes have a smaller footprint compared to forklifts, which require wide aisles and turning space. This can lead to better use of floor space and more accessible work areas.

- Flexible Placement: Cranes can be mounted along exterior walls or the roof structure (e.g., monorails), further reducing the floor space they occupy.

When to Consider an Overhead Crane

- Existing On-Floor Material Movers:

- Current Challenges: If your facility relies heavily on forklifts, industrial trucks, or conveyors, and you find these systems taking up too much space or causing congestion, an overhead crane can alleviate these issues.

- Space Efficiency: Implementing an overhead crane can optimize floor space by reducing the need for large turning areas and dedicated pathways for on-floor equipment.

- Addressing Repetitive Strain Injuries:

- Worker Health: If your employees are experiencing repetitive strain injuries due to manual handling tasks, an overhead crane can reduce physical strain by automating these processes.

- Improved Ergonomics: By reducing the physical demands on workers, cranes contribute to a healthier, more productive workforce.

Choosing the Best Overhead Crane

Types of Cranes and Capacities:

- Workstation Cranes: Load capacity up to 2 tons; ideal for light, frequent lifting tasks.

- Jib Cranes: Can handle loads up to 15 tons; useful for areas with limited space but requiring extensive reach.

- Monorail Cranes: Lift up to 100 tons; suitable for production or assembly lines with high-volume needs.

- Gantry Cranes: Move loads up to 100 tons; versatile for large-scale lifting needs across varied distances.

- Bridge Cranes:

- Single Girder: Lift up to 20 tons; suitable for moderate lifting tasks.

- Double Girder: Lift up to 250 tons; ideal for heavy-duty lifting across large spans.

Key Considerations:

- Load Weight: Ensure the crane you choose can handle the maximum load weight required for your operations.

- Lift Height: Determine the necessary lift height based on your facility’s vertical space.

- Moving Distance: Assess the horizontal distance the crane needs to cover.

- Building Construction: Consider the structural capacity of your building to support the crane system.

Overhead Crane Training and Maintenance

Training:

- Compliance: A bridge, jib, monorail, gantry or overhead traveling crane must meet the safety requirements of CSA Standard CAN/CSA B167‑96 (R2007), Safety Standard for Maintenance and Inspection of Overhead Cranes, Gantry Cranes, Monorails, Hoists and Trolleys.

- Safety and Efficiency: Proper training ensures that operators use the crane safely and effectively, reducing downtime and preventing accidents. As required by section 64 of the OHS Code, for example, only competent workers authorized by the employer can operate lifting equipment such as a crane. Making Overhead Crane and Rigging Operator training a necessity. We offer both in-house or on site training.

Maintenance:

- Routine Checks: Regular maintenance and inspections are crucial to avoid unexpected breakdowns and repair costs, which can affect profitability.

- Cost Management: Incorporating maintenance into your decision process helps manage long-term costs and keeps the crane in optimal working condition.

Conclusion

If your business seeks to enhance worker safety, optimize space usage, and boost productivity, an overhead crane could be the right investment. Assess your specific needs, consider the types of cranes available, and ensure you have a plan for training and maintenance to maximize the benefits of this equipment.

For personalized recommendations or further information, feel free to reach out to experts who can guide you through selecting and implementing the best crane for your needs.