1. What is an Overhead Crane?

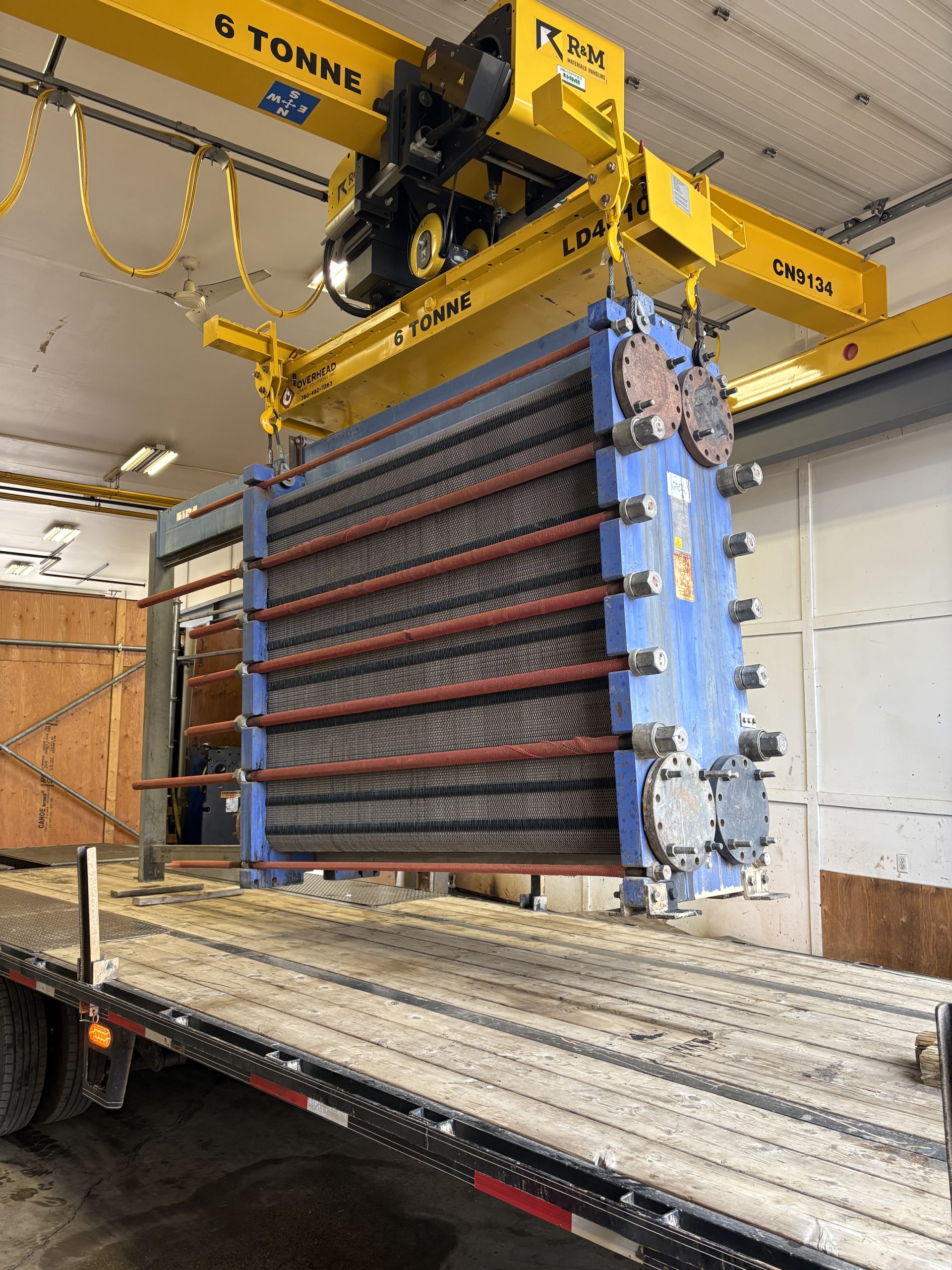

An overhead crane, often called a bridge crane, is a type of equipment used for lifting and moving heavy objects within a facility. It consists of several key components:

- Runway Beam: Mounted on columns or suspended from the ceiling.

- Bridge: Moves back and forth along the runway beam.

- Hoist: Attached to the trolley and responsible for lifting and lowering objects.

- Trolley: Moves along the bridge to position the hoist over the load.

Overhead cranes are versatile and can be operated manually or with remote controls. They are commonly used in manufacturing, warehouses, and other industrial settings for tasks such as moving raw materials, loading machinery, and performing maintenance.

2. How Do Overhead Cranes Work?

Overhead cranes operate by utilizing a system of beams, trolleys, and hoists to move heavy loads. Here’s a simplified overview:

- Runway Beam: The crane’s bridge travels along this beam, which is mounted on columns or suspended from the ceiling.

- Bridge: Moves horizontally along the runway beam and supports the hoist.

- Hoist and Trolley: The hoist lifts and lowers the load, while the trolley moves the hoist along the bridge.

- Operation: The crane is controlled via a pendant or remote control. The operator positions the crane over the load, secures it with hooks or slings, and then moves it to the desired location.

3. Types of Overhead Cranes

- Single Girder Overhead Crane: Features one beam and is suitable for lighter loads (up to 20 tons).

- Double Girder Overhead Crane: Has two beams for increased stability and higher load capacity (up to 250 tons).

- Gantry Crane: Supported by legs, it moves on the ground and is used for outdoor applications.

- Jib Crane: Features a horizontal arm that can rotate, ideal for localized lifting tasks.

- Monorail Crane: Moves along a single beam, used for specific paths like assembly lines.

- Underhung Crane: Runs on the underside of a runway beam, suitable for low headroom situations.

4. Weight Capacity of Overhead Cranes

The weight capacity of an overhead crane varies depending on its type and configuration. Typical ranges are:

- Single Girder: up to 20 tons.

- Double Girder: up to 250 tons or more.

- Gantry Cranes: up to 100 tons or more.

The crane’s load capacity is determined by its structural components and design. It’s crucial to select a crane with a suitable capacity to ensure safety and efficiency. The above numbers are just a typical guideline, with evolving systems the capacities can reach up to 1000 tons + depending on certain factors.

5. Safety Features of Overhead Cranes

- Overload Protection: Prevents lifting loads beyond the crane’s capacity.

- Emergency Stop Button: Allows for immediate shutdown in emergencies.

- Limit Switches: Prevents movement beyond designated boundaries.

- Anti-Collision Systems: Monitors and prevents collisions between multiple cranes.

- Fail-Safe Brakes: Engage automatically if power is lost.

- Warning Devices: Includes lights and alarms to signal crane movements.

- Operator Training: Ensures that operators are properly trained in crane use.

6. Inspection and Maintenance of Overhead Cranes

Inspections:

- Pre-Operational: Daily visual checks before use.

- Frequent: Weekly to quarterly inspections of wear-prone parts.

- Periodic: Comprehensive examinations every 6 to 12 months by a licensed inspector.

Maintenance:

- Daily: Visual inspections by operators.

- Regular: Scheduled replacement and lubrication.

- Preventive: Regular checks and part replacements to avoid failures.

- Emergency: Immediate repairs as needed.

7. Advantages of Using Overhead Cranes

- High Lifting Capacity: Capable of moving heavy loads efficiently.

- Improved Safety: Reduces manual handling and associated risks.

- Increased Efficiency: Speeds up material handling processes.

- Reduced Footprint: Saves floor space by utilizing overhead paths.

- Wide Range of Applications: Versatile in various industries and tasks.

- Improved Precision: Allows for accurate positioning of loads.

8. Choosing the Right Overhead Crane

Consider the following factors:

- Lifting Capacity: Match the crane’s capacity with the maximum load weight.

- Span and Lift Height: Ensure the crane fits the required span and height.

- Environment: Choose materials and features suitable for indoor or outdoor use.

- Speed and Accuracy: Select a crane with appropriate speed and precision for your tasks.

- Safety: Ensure the crane has necessary safety features.

- Maintenance and Repair: Consider ease of maintenance and availability of spare parts.

9. Installing an Overhead Crane

- Planning: Identify the installation location and prepare the site.

- Unpacking and Prep Work: Check components for damage and prepare the installation area.

- Installing Beams: Set up the horizontal beams for crane movement.

- Installing the Hoist: Attach the hoist to the bridge.

- Runway Installation: Secure the crane runway and install necessary systems.

- Wiring: Install and test electrical systems.

- Final Testing: Conduct thorough testing and adjustments before use.

10. Operating an Overhead Crane Safely

- Follow Guidelines: Adhere to the manufacturer’s instructions.

- Inspect Equipment: Perform visual checks before operation.

- Use PPE: Wear appropriate personal protective equipment.

- Know the Capacity: Ensure the load does not exceed the crane’s capacity.

- Check the Load: Ensure the load is stable and properly secured.

- Communicate Clearly: Maintain clear communication with all involved personnel.

- Be Aware of Surroundings: Watch for obstacles and maintain a clear path.

11. Load Capacity Crane

A load capacity crane refers to the maximum weight a crane can safely lift. This is a critical specification to ensure the crane can handle the intended loads without compromising safety.

12. Material Handling Crane

A material handling crane is designed to lift and move heavy materials within industrial settings. Types include:

- Gantry Cranes: Used for outdoor heavy lifting.

- Jib Cranes: Ideal for confined spaces.

- Bridge Cranes: Used for moving heavy loads across facilities.

These cranes are essential for efficient material movement and safety in various industrial applications.