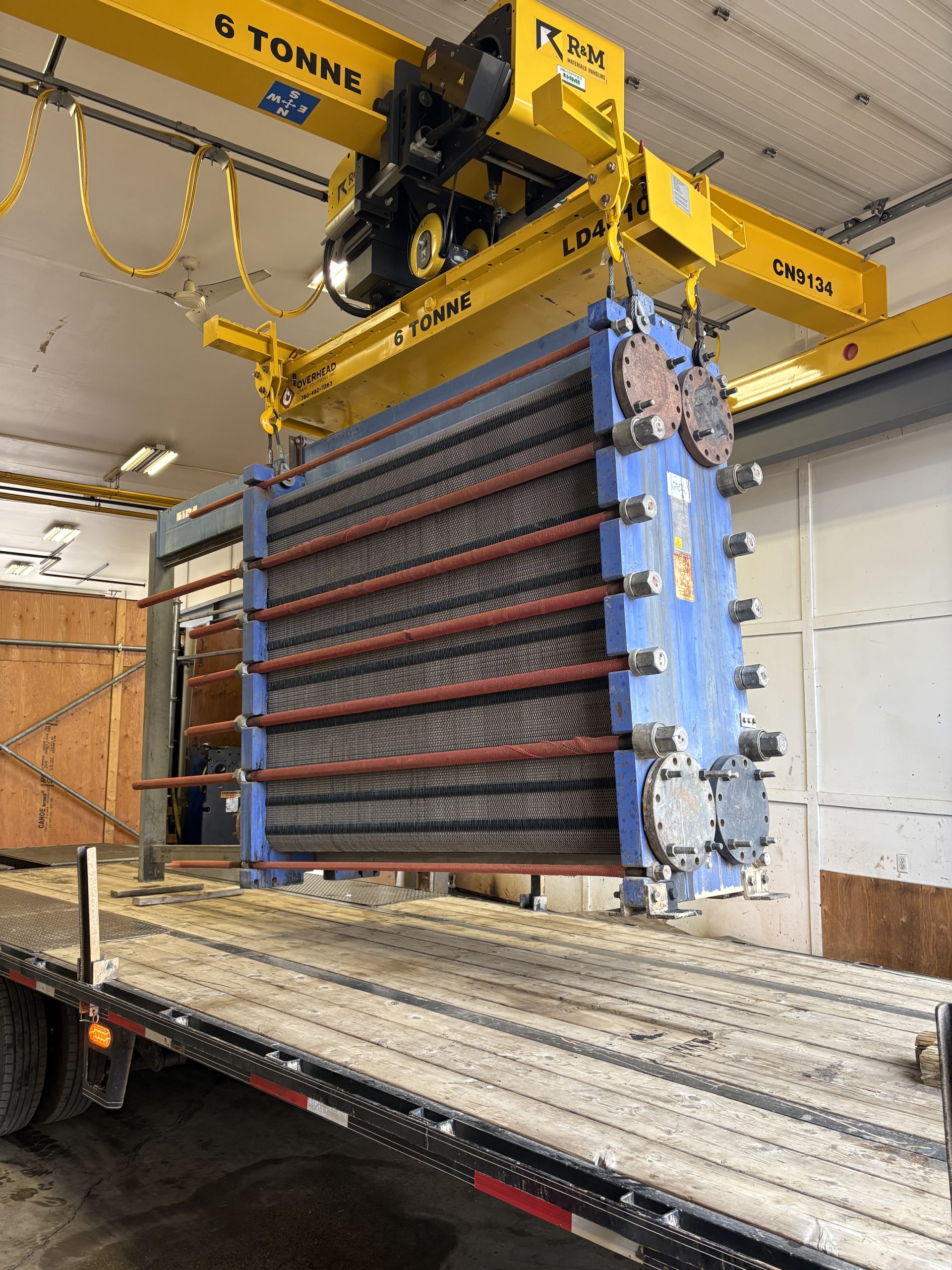

Workstation Cranes Overview

Workstation cranes are specialized ergonomic devices designed to assist workers in handling materials efficiently and safely. They are particularly valuable in manufacturing and processing environments, where they help move components or materials from one workstation to another, minimizing the risk of injury associated with manual lifting.

Design and Functionality:

- Structure: Workstation bridge cranes consist of a bridge beam (or beams) supported by end trucks at either end. These end trucks move along fixed runways, allowing the bridge to traverse a rectangular area, typically covering both horizontal and vertical movements.

- Load Capacity: They can handle loads ranging from 250 to 4,000 pounds, making them versatile for various applications.

- Movement: The crane moves loads both side-to-side and forward-and-backward along the bridge. The hoist or other lifting attachments on the bridge enable vertical lifting of materials.

- Relocation: One of the key advantages is their easy relocation capability. This flexibility makes them ideal for facilities with changing workflows or for temporary setups in rented spaces.

Installation Options:

- Ceiling-Mounted Systems:

- Attachment: These cranes attach directly to existing ceiling support structures, such as beams or trusses.

- Space Efficiency: They utilize overhead space, leaving the floor area unobstructed and optimizing the use of workspace without interfering with ground operations.

- Considerations: Suitable when the building’s ceiling structure is robust enough to support the crane and if future relocation is not a primary concern.

- Freestanding Systems:

- Support: Supported by independent columns that do not rely on the existing building structure.

- Flexibility: Ideal for large areas or when future relocation might be necessary. They can be installed in virtually any facility without needing to adapt to existing overhead structures.

- Cost-Effectiveness: Often more affordable for larger coverage areas where utilizing existing building support is impractical.

Advantages of Workstation Bridge Cranes

- Ergonomics: By reducing manual lifting, they minimize the risk of worker injury and strain, contributing to a safer workplace.

- Efficiency: They streamline material handling processes, reducing the need for multiple jib cranes or forklifts and allowing for more efficient use of overhead cranes for larger loads.

- Flexibility: Their ability to be relocated and reconfigured makes them adaptable to changing needs and facility layouts.

Choosing the Right System

When selecting between ceiling-mounted and freestanding workstation bridge crane systems, consider the following factors:

- Available Space: Ceiling-mounted systems save floor space, while freestanding systems are better for areas where ceiling structures may not be available or strong enough.

- Future Plans: If you anticipate relocating or expanding your operations, freestanding systems offer more flexibility.

- Building Structure: Evaluate the strength and configuration of existing ceiling structures for ceiling-mounted options.

In summary, workstation bridge cranes are a valuable tool for improving material handling efficiency and safety in various industrial settings. Their design flexibility, ease of relocation, and ergonomic benefits make them a practical choice for many applications.